Copper Wire

Products

With the technical cooperation with GE Company of the USA and Showa electric Company of Japan, we adopted the pollution free “Dip Forming” process to make Oxygen-Free Copper Rod.

There is no problem of pollution and no dust. It does not require picking, with 102% conductivity. Our copper rods are the best raw materials available for Wire and Cable Industry.

Products Name | Type | Size | Application |

Oxygen-Free Copper Rod | Oxygen-Free copper(Oxygen content under 15ppm) | 8.00mmf /9.50mmf | Raw-material of different kinds of copper conductor and cable |

Oxygen-Free Copper Wire | Oxygen-Free copper(Oxygen content under | 0.40mmf~3.20mmf | |

Oxygen-Free Copper Lead Wire for Electronic Company | Oxygen-Free copper(Oxygen content under 15ppm) Semi-Rigid | 0.78mmf /1.28mmf | Lead wire of electronic parts |

Stranded Bare Copper Wire | CNS,ICEA,JIS,BS,VDEA,H,TH,TA,PH WIRE | 2mm2~1000mm2 | Used for overhead Distribution line, lead wire of electric oven, etc. |

Silver copper Alloy Wire | 0.40mm2~1.50mm2 | Used in precision electronic lead wire (The silver contents are according to customer’s |

Oxygen-Free Copper Rod Manufacturing Process

Oxygen-Free Copper Wire

Oxygen Free Copper Rod is manufactured in continuous DIP FORMING PROCESS from electrolytic copper plate. The whole process that includes DIPPING, FORMING and HOT ROLLING are taken in reductive atmosphere without oxygen and hydrogen (oxygen content under 15PPM). The high purity copper rod and wire have those characteristics below, which are suitable for the high conductivity power cable, telecom cable, fine magnet wire and electronic wire.

Features

1、The Manufacture Process and Characteristics of Oxygen Free Copper Rod

Our Oxygen Free Copper Rod is manufactured in continuous DIP FORMING PROCESS from electrolytic copper plate. The whole process that includes DIPPING, FORMING and HOT ROLLING are taken in reductive atmosphere without oxygen and hydrogen. The high purity copper rod and wire have those characteristics below, which are suitable for the high conductivity power cable, telecom cable, fine magnet wire and electronic wire.

(1) Oxygen content is less than 15PPM, the average conductivity is 101%, higher than the other processes wire

(2) The particle grain is fine and excellent in twisting and drawing

(3) Less impurity, scrap and spur easy for fine wire drawing without break

(4) Smooth and bright surface, good adhesion in tin plating and enamel coating (Especially for rectangular wire)

(5) Extra low oxygen content, will not be brittle that caused by hydrogen

(6) Continuous process, the weight of each coil can be assigned by customer (Max 4 Tons)

2、The characteristic comparisons of 2.0mmf soft oxygen free copper wire

| Item | CNS 1364 C2030 | DIP Process | SCR Process |

|---|---|---|---|

| Copper Purity (%) | > 99.90 | 99.99 | 99.97 |

| Oxygen Content(ppm) | - | < 15 | 300~400 |

| Conductivity (%) | > 100.00 | > 100.0 | > 100.0 |

| Tensile Stress (kg/mm2) | < 27.00 | < 27.00 | < 27.00 |

| Elongation(%) | > 30.00 | > 30.00 | > 30.00 |

| Surface | Smooth | Smooth & Bright | Little Rough |

| Drawing Process | - | Excellent | Good |

| Brittle by Hydrogen | - | Good | Poor |

Specifications

1、The classifications and specifics of copper wires

| Products Name | Symbol | Size Range(mm) | Applications |

|---|---|---|---|

| Copper rod | 0CU | 8.0f、9.5f | For rod break-down M/C |

| Bare copper wire | 0CU-S ( Soft wire) | 0.03f ~ 3.2f | 1、For middle through fine wire drawing M/C 2、Conductor of electrical wire, cable and magnet wire |

0CU-M (Middle hard wire) | |||

0CU-H (Hard wire) |

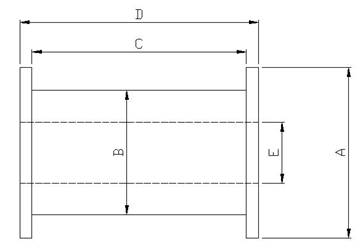

2、The packaging type and bobbin size:

A、Bare copper wire for 0.03~1.2 mm

| item symbol | A | B | C | D | E | Max. capacity |

|---|---|---|---|---|---|---|

| P10 | 199 | 161 | 180 | 216 | 80 | 10kg |

| 40K(short) | 280 | 200 | 214 | 235 | 73 | 40kg |

| 40K(long) | 280 | 214 | 279 | 300 | 115 | 40kg |

| 60K | 300 | 216 | 280 | 305 | 115 | 60kg |

| 70K | 318 | 214 | 280 | 305 | 115 | 70kg |

| 100K(short) | 400 | 265 | 250 | 277 | 133 | 100kg |

| 100K(long) | 365 | 270 | 350 | 375 | 133 | 100kg |

| 150K | 450 | 280 | 280 | 300 | 133 | 150kg |

| 200K | 450 | 315 | 400 | 430 | 133 | 200kg |

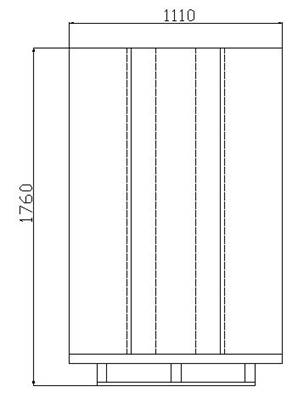

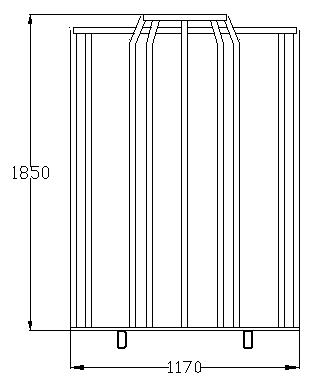

B、Bare copper wire for 1.3~3.2 mm (Max. Capacity about 2.5 tons)

B1、Basket for domestic

B2、Paper basket for overseas