TIW Wire

Products

|  |  |

| TIW-B(130C) | TIW-B(130C) | TIW-B2(130C) |

|  |  |

| TIW-B2(130C) | TIW-F(155C) | TIW-F(155C) |

|  | |

| TIW-F(155C) | TLW-B7S |

Special Transformer Winding Wire (Triple insulated winding wire)

TIW –B & TIW-B2 &TIW-F is a high temperature resistant resin, It has outstanding mechanical, electrical, electrical and chemical properties suitable for electrical wire insulation, it was invented by Du Pont in 1971 Chemically TEFZEL is a copolymer of ethylene and tetrafluoroethylene. Melting point 270℃, temperature rating 150℃~200℃.

Structure | |

| Single conductor - Single strand can use bare copper wire / enameled copper / tin plating lines etc. , and enamel insulation coating layer. |

| Lize-Multi-strand insulated copper magnet wire coated with enamel insulation layer. |

| In case you have special needs, please contact us. |

Features | |

| Small size:Suitable to design the smaller product. |

| Light weight:Special transformer winding wire have a lower density than other insulation, therefore decrease the weight. |

| Excellent character:Because have many insulated layers, so can decrease the pinhole, therefore increase the resisted voltage. |

Use | |

| Transformer |

| Power supply |

| High frequency coil |

| Temperature Thermistor |

TIW –B

THREE LAYER INSULATION WIRE(TIW-B)

Size Table

| Conductor | Insulation Covering | Max Conductor Resistance | Min. | TOTAL

| G.W (INCLUED PAPER BOX & PVC REEL WEIGHT) | |||||

Diameter(mm) | Teleranc | Target | Max Target | |||||||

0.10 | ±0.008 | 0.30 | 0.335 | 2264.7 | 15 | 5000M*2R | 2.236 | |||

0.11 | ±0.008 | 0.31 | 0.345 | 2153.0 | 15 | 5000M*2R | 2.416 | |||

0.12 | ±0.008 | 0.32 | 0.335 | 1786.0 | 15 | 5000M*2R | 2.596 | |||

0.13 | ±0.008 | 0.33 | 0.365 | 1505.0 | 15 | 5000M*2R | 2.756 | |||

0.14 | ±0.008 | 0.34 | 0.375 | 1286.0 | 15 | 5000M*2R | 3.026 | |||

0.15 | ±0.008 | 0.35 | 0.385 | 1111.0 | 15 | 5000M*2R | 3.246 | |||

0.16 | ±0.008 | 0.36 | 0.395 | 969.5 | 15 | 5000M*2R | 3.526 | |||

0.17 | ±0.008 | 0.37 | 0.405 | 853.5 | 15 | 5000M*2R | 3.776 | |||

0.18 | ±0.008 | 0.38 | 0.415 | 757.2 | 15 | 5000M*2R | 4.076 | |||

0.19 | ±0.008 | 0.39 | 0.425 | 676.2 | 15 | 5000M*2R | 4.326 | |||

0.20 | ±0.008 | 0.40 | 0.417 | 607.6 | 15 | 5000M*2R | 4.676 | |||

0.21 | ±0.008 | 0.41 | 0.427 | 549.0 | 15 | 4000M*2R | 4.236 | |||

0.22 | ±0.008 | 0.42 | 0.437 | 498.4 | 15 | 4000M*2R | 4.396 | |||

0.23 | ±0.008 | 0.43 | 0.447 | 454.5 | 15 | 5000M | 2.923 | |||

0.24 | ±0.008 | 0.44 | 0.457 | 416.2 | 15 | 5000M | 3.123 | |||

0.25 | ±0.008 | 0.45 | 0.467 | 382.5 | 15 | 5000M | 3.323 | |||

0.26 | ±0.01 | 0.46 | 0.477 | 358.4 | 15 | 5000M | 3.523 | |||

0.27 | ±0.01 | 0.47 | 0.487 | 331.4 | 15 | 5000M | 3.723 | |||

0.28 | ±0.01 | 0.48 | 0.497 | 307.3 | 15 | 5000M | 3.923 | |||

0.29 | ±0.01 | 0.49 | 0.507 | 285.7 | 20 | 5000M | 4.123 | |||

0.30 | ±0.01 | 0.50 | 0.520 | 262.9 | 20 | 5000M | 4.548 | |||

0.32 | ±0.01 | 0.52 | 0.540 | 230.0 | 20 | 5000M | 5.023 | |||

0.35 | ±0.01 | 0.55 | 0.570 | 191.2 | 20 | 5000M | 5.773 | |||

0.37 | ±0.01 | 0.57 | 0.590 | 170.6 | 20 | 4000M | 5.023 | |||

0.40 | ±0.01 | 0.60 | 0.625 | 145.3 | 20 | 4000M | 6.023 | |||

0.45 | ±0.01 | 0.65 | 0.675 | 114.2 | 20 | 3000M | 5.723 | |||

0.50 | ±0.01 | 0.70 | 0.725 | 91.43 | 20 | 3000M | 6.713 | |||

0.55 | ±0.02 | 0.75 | 0.775 | 78.15 | 20 | 2000M | 5.623 | |||

0.60 | ±0.02 | 0.80 | 0.825 | 65.26 | 20 | 2000M | 6.323 | |||

0.65 | ±0.02 | 0.85 | 0.875 | 55.31 | 20 | 2000M | 7.423 | |||

0.70 | ±0.02 | 0.90 | 0.925 | 47.47 | 20 | 1500M | 6.323 | |||

0.75 | ±0.02 | 0.95 | 0.975 | 41.19 | 20 | 1500M | 7.223 | |||

0.80 | ±0.02 | 1.00 | 1.030 | 36.08 | 20 | 1000M | 5.623 | |||

0.85 | ±0.02 | 1.05 | 1.080 | 31.87 | 20 | 1000M | 6.323 | |||

0.90 | ±0.02 | 1.10 | 1.130 | 28.35 | 20 | 1000M | 6.823 | |||

0.95 | ±0.02 | 1.15 | 1.180 | 25.38 | 20 | 1000M | 7.323 | |||

1.00 | ±0.03 | 1.20 | 1.230 | 23.33 | 20 | 1000M | 8.623 | |||

TIW-B2

Two Layer Insulation Wire (TIW-B2)

Size Table

| Conductor | Insulation Covering | Max Conductor Resistance | Min. | Packlist

| |||||

Diameter(mm) | Teleranc | Target | Telerance | ||||||

0.10 | ±0.008 | 0.26 | ±0.004 | 2264.7 | 15 | 5000*2 | |||

0.11 | ±0.008 | 0.27 | ±0.004 | 2153.0 | 15 | 5000*2 | |||

0.12 | ±0.008 | 0.28 | ±0.004 | 1786.0 | 15 | 5000*2 | |||

0.13 | ±0.008 | 0.29 | ±0.004 | 1505.0 | 15 | 5000*2 | |||

0.14 | ±0.008 | 0.30 | ±0.004 | 1286.0 | 15 | 5000*2 | |||

0.15 | ±0.008 | 0.31 | ±0.004 | 1111.0 | 15 | 5000*2 | |||

0.16 | ±0.008 | 0.32 | ±0.004 | 969.5 | 15 | 5000*2 | |||

0.17 | ±0.008 | 0.33 | ±0.004 | 853.5 | 15 | 5000*2 | |||

0.18 | ±0.008 | 0.34 | ±0.004 | 757.2 | 15 | 5000*2 | |||

0.19 | ±0.008 | 0.35 | ±0.004 | 676.2 | 15 | 5000*2 | |||

0.20 | ±0.008 | 0.36 | ±0.004 | 607.6 | 15 | 5000*2 | |||

0.21 | ±0.008 | 0.37 | ±0.004 | 549.0 | 15 | 4000*2 | |||

0.22 | ±0.008 | 0.38 | ±0.004 | 498.4 | 15 | 4000*2 | |||

0.23 | ±0.008 | 0.39 | ±0.004 | 454.5 | 15 | 5000 | |||

0.24 | ±0.008 | 0.40 | ±0.004 | 416.2 | 15 | 5000 | |||

0.25 | ±0.008 | 0.41 | ±0.005 | 382.5 | 15 | 5000 | |||

0.26 | ±0.008 | 0.42 | ±0.005 | 358.4 | 15 | 5000 | |||

0.27 | ±0.01 | 0.43 | ±0.05 | 331.4 | 15 | 5000 | |||

0.28 | ±0.01 | 0.44 | ±0.05 | 307.3 | 15 | 5000 | |||

0.29 | ±0.01 | 0.45 | ±0.05 | 285.7 | 20 | 5000 | |||

0.30 | ±0.01 | 0.46 | ±0.05 | 262.9 | 20 | 5000 | |||

0.32 | ±0.01 | 0.48 | ±0.05 | 230.0 | 20 | 5000 | |||

0.35 | ±0.01 | 0.51 | ±0.05 | 191.2 | 20 | 5000 | |||

0.37 | ±0.01 | 0.53 | ±0.05 | 170.6 | 20 | 4000 | |||

0.40 | ±0.01 | 0.56 | ±0.05 | 145.3 | 20 | 4000 | |||

0.45 | ±0.01 | 0.61 | ±0.05 | 114.2 | 20 | 3000 | |||

0.50 | ±0.01 | 0.68 | ±0.05 | 91.43 | 20 | 3000 | |||

0.55 | ±0.02 | 0.71 | ±0.05 | 78.15 | 20 | 2000 | |||

0.60 | ±0.02 | 0.76 | ±0.05 | 65.26 | 20 | 2000 | |||

0.65 | ±0.02 | 0.81 | ±0.05 | 55.31 | 20 | 2000 | |||

0.70 | ±0.02 | 0.86 | ±0.05 | 47.47 | 20 | 1500 | |||

0.75 | ±0.02 | 0.91 | ±0.05 | 41.19 | 20 | 1500 | |||

0.80 | ±0.02 | 0.96 | ±0.05 | 36.08 | 20 | 1000 | |||

0.85 | ±0.02 | 1.01 | ±0.05 | 31.87 | 20 | 1000 | |||

0.90 | ±0.02 | 1.06 | ±0.05 | 28.35 | 20 | 1000 | |||

0.95 | ±0.02 | 1.11 | ±0.05 | 25.38 | 20 | 1000 | |||

1.00 | ±0.03 | 1.16 | ±0.05 | 23.33 | 20 | 1000 | |||

TIW-B &TIW-B2 PACKAGE INFO.

CARTOON SIZE: 186MM(L) X256MM(H) X180MM(W)

CARTOON WEIGHT: 0.245KGS

Detailed Product Description

Characters:

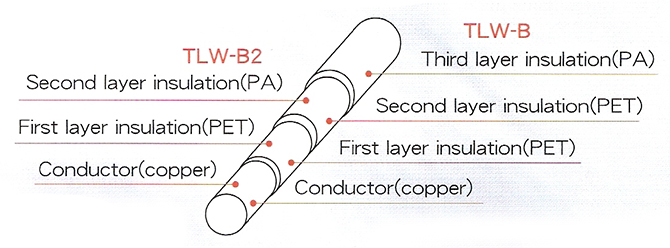

1). The TIW-B2( supplementary insulation) and the TIW-B (Reinforced insulation) manufactured by Round Teck are made of copper conduct covered by 2 or 3 extruded insulation layers, and matched the requirements of UL-2353. They may use for transformers directly and save the materials of interlayer-insulation, stop wall and sleeve etc.

2). Without using interlayer-insulations, transformers may have smaller volume,and save the total material and manufacture cost.

3).TLW-B can weld with welding tin directly without peeling outer insulation layer first.

4). TLW-B also can be manufactured to be peeling easily for manufacturing needs.

Certificates:

UL Files: No E236542

VDE License No:40008834

IEC 60950-1 (ed 1)

DIN EN 60950-1 (VDE 0805 Tall) 2003-03

EN 60950-1 (Ed 1) 2001-12

Matched the requirements of :

EUROPE: European Union Restriction of the Use of Certain

Hazardous Subsances: ROHS

Japan: SONY SS-00259 Sony Technical Standard

SPECIFICATIONS:

Product Diameters: 0.10mm - 1.00mm

Temperature Indicator: 105C, 120C,130C

Any two insulation layers of TLW-B, should passed 3000V-1 Minute voltage-durable test.

The voltage-durable limitation is up to 10KV

Several colors of TLW-B could be made for customer's

APPLICATION FILEDS:

Cell Phones, Printers, Re-Charges of digital camera, converters of personal computers,DVC...etc

MSDS

<TD">7440-50-8 100%

| Description: TIW-B | ||||||

No. | MATERIAL NAME | Material P/N | COMPONENT | Content Percentage | CAS NO | Composition Percentage |

1 | Conductor | OFC | STEEL | 93% | ||

| 2 | PET polyethylene terephthalate | PET-01 | PET | 5% | 25038-59-9 | 100% |

3 | PA poly amide | PA-01 | PA | 2% | 32131-17-2 | 100% |

2.Product/material Objectionable Constituents Content

| Deleterious substance name | Chemistry molecular formula | Test result | Customer request | Result | Test File No |

1 | Cadmium | Cd | ND | Based on customer’s request | Ok | KA/2008/41145A-01R1 |

2 | Lead | Pb | ND | Same as above | Ok | KA/2008/41145A-01R1 |

3 | Mercury | Hg | ND | Same as above | Ok | KA/2008/41145A-01R1 |

4 | Six chromium | Cr6+ | ND | Same as above | Ok | KA/2008/41145A-01R1 |

5 | Multi- bromines biphenyl class | PBB | ND | Same as above | Ok | KA/2008/41145A-01R1 |

6 | Multi- bromines diphenyl oxide | PBDE | ND | Same as above | Ok | KA/2008/41145A-01R1 |

| Other info.please see SGS report KA/2008/41145A-01R1 |

|

|

|

| |